Description

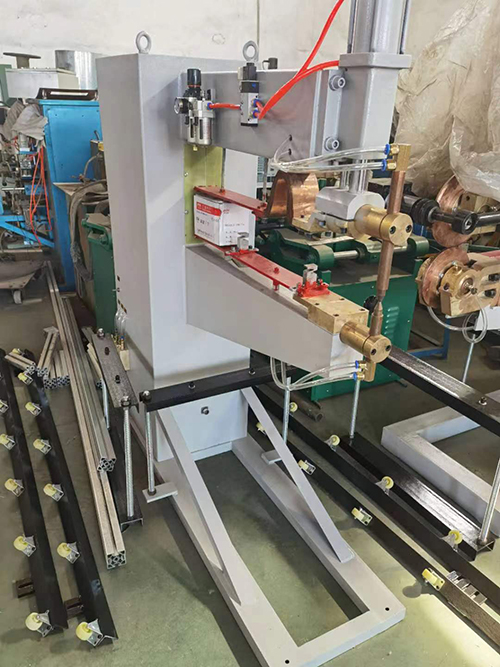

Automatic shearing machine

Production speedAbout 15 meters/1 minute

Feed width≦1.3 meters

Side panel thickness30mm

Leveling thickness ≦1mm cold rolled plate, galvanized plate

80T Punching Machine

| Nominal force | 800 |

| Nominal force stroke | 4 |

| Number of trips | 35-80 |

| Slider stroke | 150 |

| Maximum mold height | 340 |

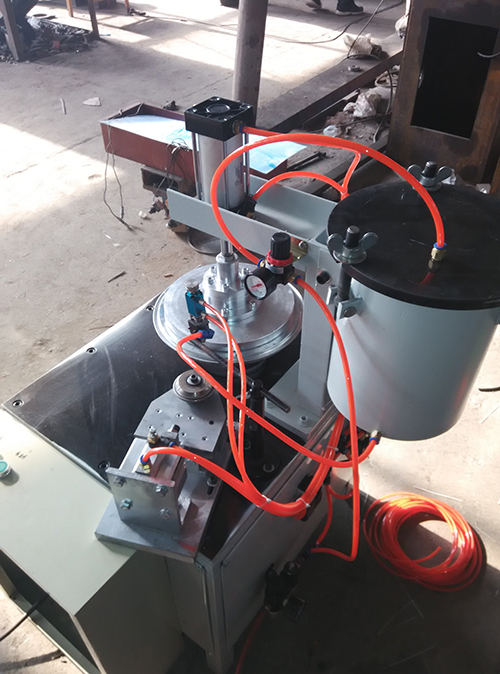

Pre-roll glue injection machine:

The straight edge of the bottom of the barrel is pre-rolled and filled with sealant.The main technical parameters:Input power: AC380V/50HZ. Total motor power: 6.2 kWWork efficiency: 6/min. Workpiece diameter: 343mmEquipment weight: 500Kg Workpiece thickness: 0.5-0.8mm

Overall dimensions: 1600*1000*1000.

=

=

Reviews

There are no reviews yet.