Description

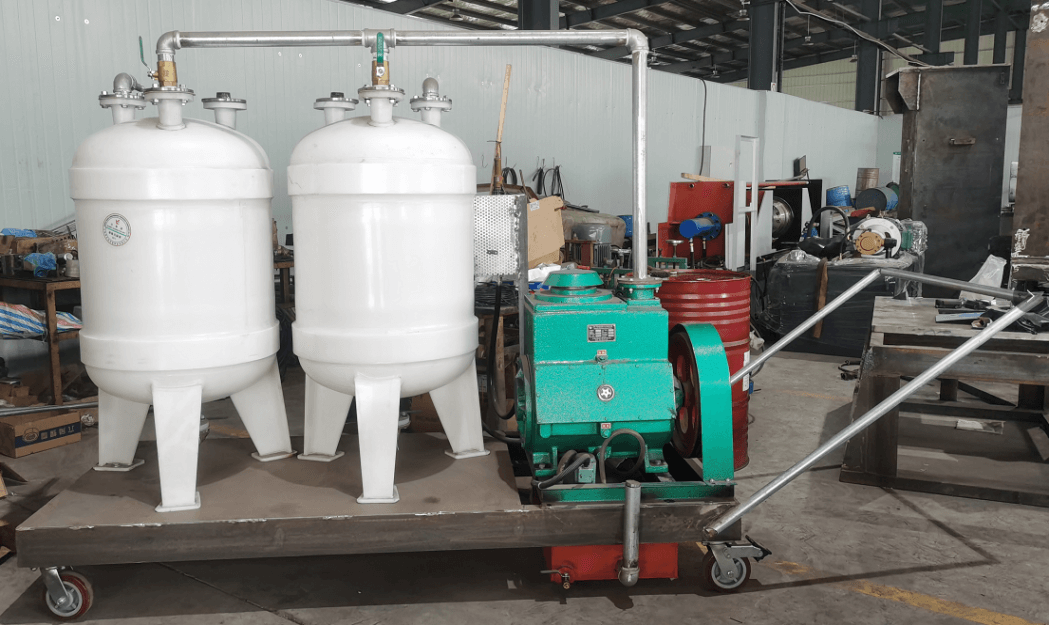

1. Water ring vacuum residual liquid suction machine

By sucking the residual liquid machine, the different residual liquid in the waste drum is pumped into different storage tanks for the next step.

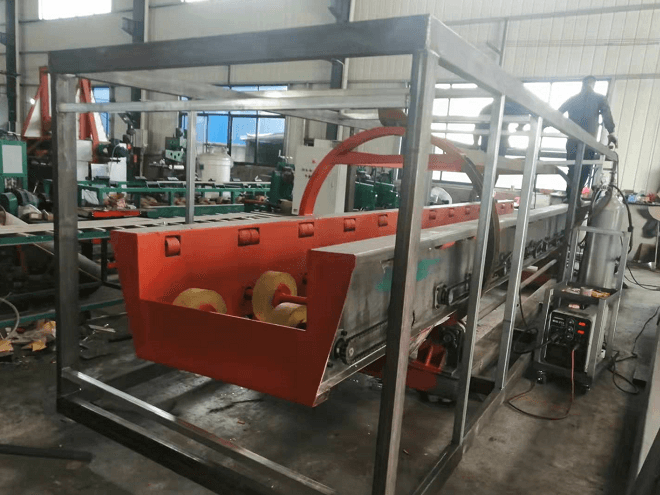

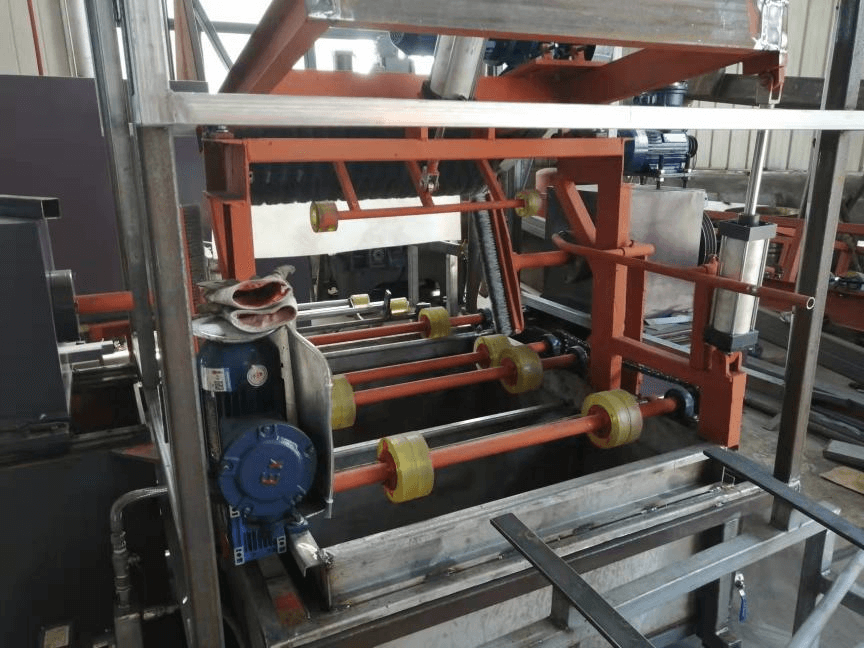

2. Automatic re-shaping machine

The waste drums that need to be reshaped are sent to the reshaping process for restoration treatment, and the drums are restored to the quantitative filling machine.

3. Automatic filling machine

Send the waste drum that does not need to be reshaped into the quantitative filling machine, put in a certain amount of cleaning solvent and abrasive (a 2-meter iron chain), and then tighten the screw cap (Oil drum like put in about 3.5 kg of lye), after filling the cleaning liquid, send it to the conveyor belt, and enter the automatic internal and external cleaning machine for cleaning.

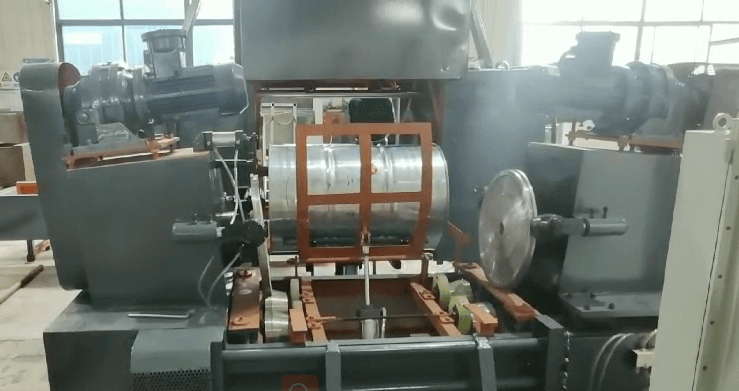

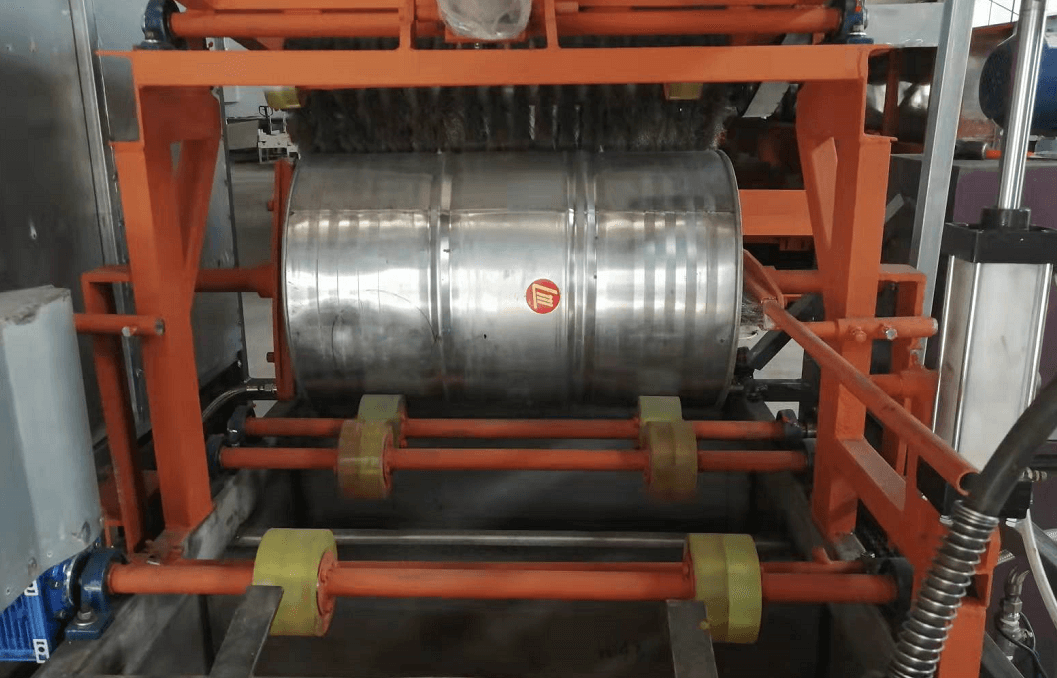

4.Automatic cleaning machine

The drum with the cleaning liquid and screw cap is sent to the fully automatic closed internal and external washing machine through the conveyor belt for cleaning (the tilt of the drum washing machine can be adjusted arbitrarily within the range of 0-80°, and it can be cleaned into the drum from all angles), after cleaning, enter the next process through the conveyor chain

4.1 Inside cleaning

4.2 Outside cleaning

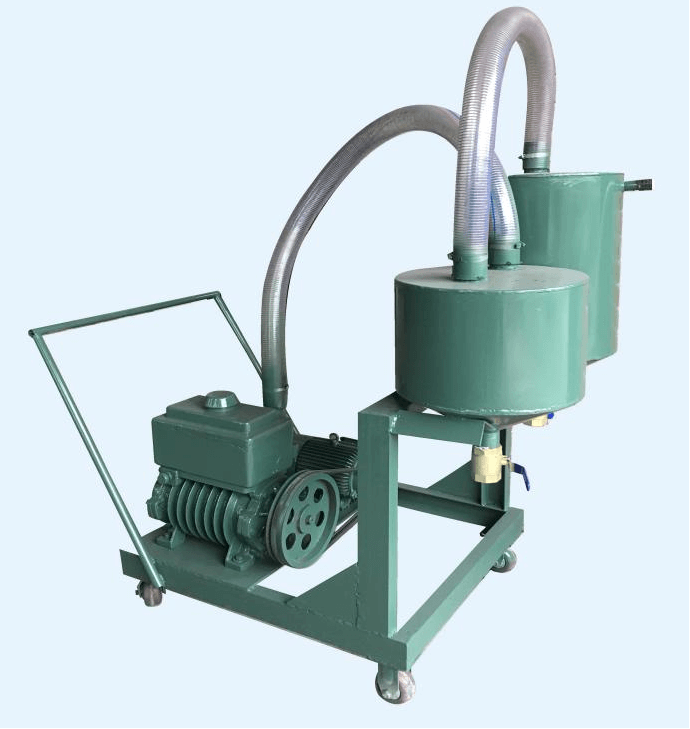

5.Vacuum suction machine

The residual liquid and waste in the drum are sucked by the vacuum pump.

6.Leakage testing machine

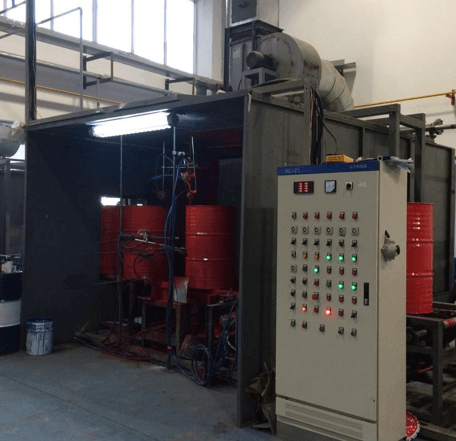

7.Painting spray booth

8.Drying oven

Reviews

There are no reviews yet.