Automatic Steel Drum Seam Welding Machine is an important device for producing metal drums. Its working principle belongs to the scope of resistance welding: that is, after the work pieces are assembled, the electrode applies pressure and the current flows through the steel plate. The contact area of the overlap and the adjacent area generate resistance heat, thereby forming a series of overlapped nuggets to obtain an airtight weld.

The welding method adopted by this equipment is roll seam welding. The electrode is a cylindrical roller. Its width is larger than the overlap of the steel plate to control the thickness of the joint. Welding uses a large electrode pressure and continuous welding current. By controlling welding specifications, including parameters such as electrode pressure, welding current, and welding speed, stable welding quality can be obtained, and seam welding procedures for longitudinal welds with a diameter of 560 mm to 571.6 mm can be completed.

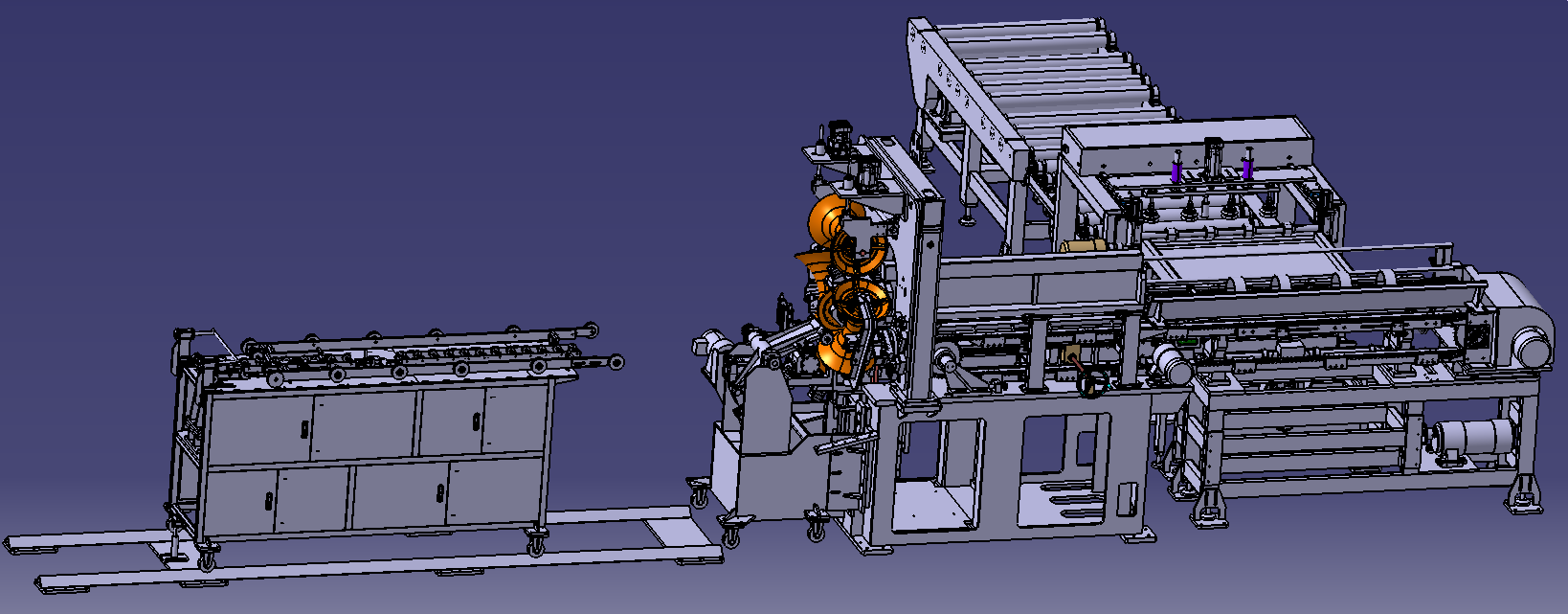

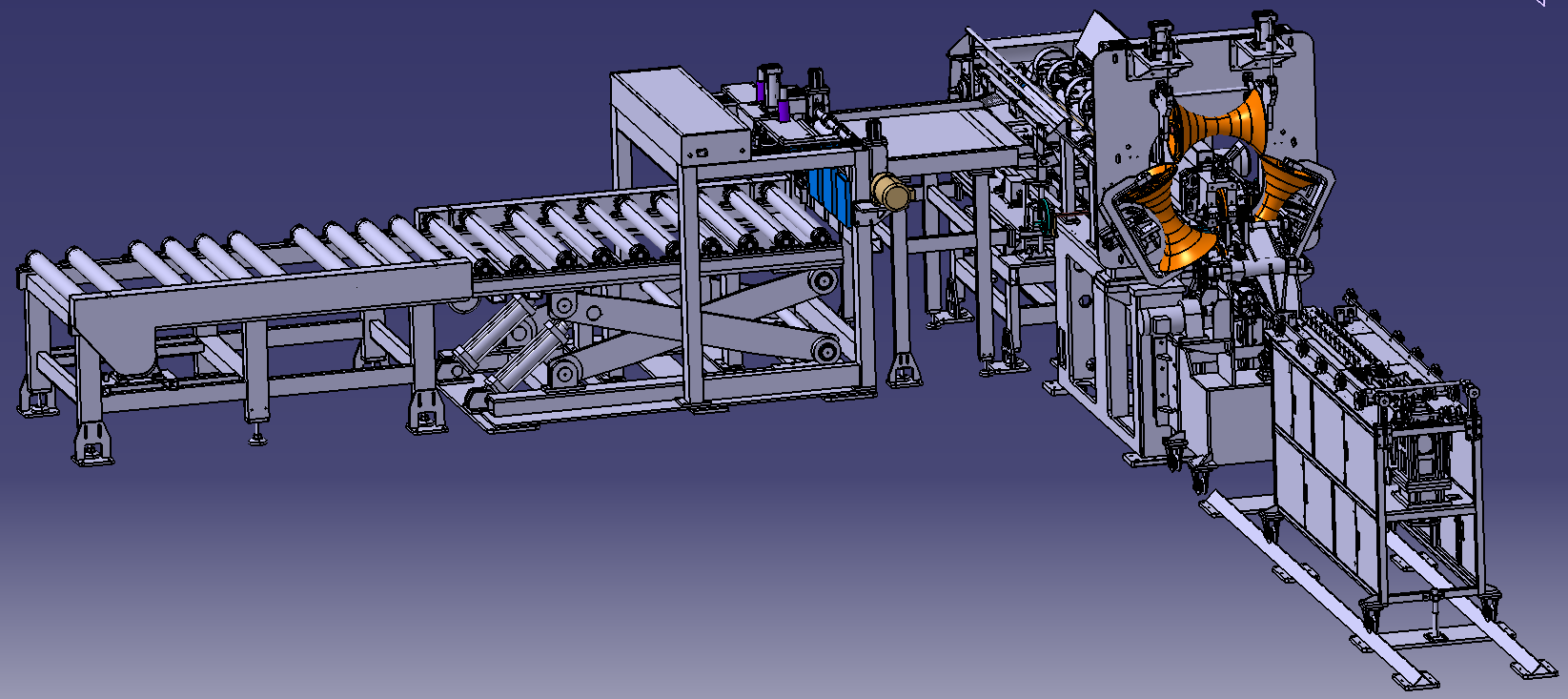

Machine appearance and structure