During the spraying process, when the paint mist mixed in the air hits the water curtain, the paint mist is washed, and the water curtain on the water curtain is turned by the venturi principle through the effect of the exhaust fan, so that the paint mist and water mist are fully mixed. Then, the air and water are separated by spraying and baffling secondary filtration, thereby reducing the moisture in the air, giving the operator a clean working environment, and the purification rate of paint mist can reach more than 90%.

After filtering, the paint mist flows into the water tank and floats on the water surface by condensing together in the water tank to facilitate cleaning. The water curtain spray booth adopts side air extraction structure, which has high dust removal efficiency, uniform spray, small water consumption, and covers an area small.

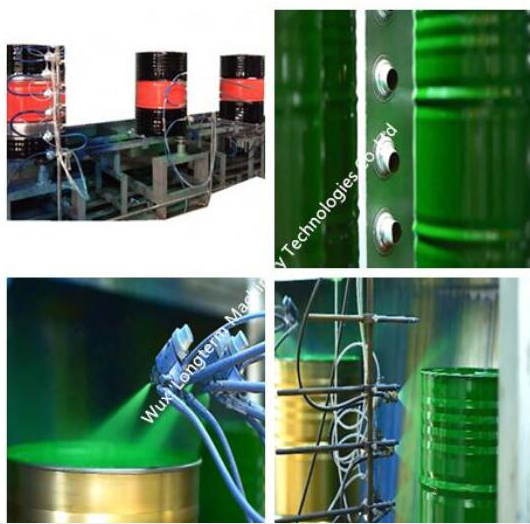

Steel Drum Painting Machine Pictures

| Dimension | 6000*4320*4000mm |

| Material | the structure is carbon steel; the sink, water curtain, Water vapor separation room is ss304 |

| Purification method | Water curtain + shower + water vapor separator; solvent volatile gas is sent to the atmosphere |

| Pinch form | Two sets of fully enclosed steel drum rotating machines with four supporting wheels; one set of lifting rotating machine |

| Sprayer | 1. Europe Airless spraying machine: 3 sets; 2. Ou Naishi spray gun: ZPQ 23; 3.Nozzles: 23, using the products of American Spray System Co., 4 of them use Nordson products. |

| Spraying method | Three-color vertical spraying |

| Production capacity | 200 pcs/hour |

| PLC control cabinet | Use PLC to control spraying and transmission |

| Conveying method | Stepping |

.png)