Description

Machine Main Parameters:

The working principle of the welder are as follows:

The sheet is put between two welding rollers (the ends of the sheet will be lapped), with pressure, the welding rollers turn. With low voltage, big current and resistance radiation, the two short-cut poles generate heat which connect the working piece.

With special fixture, the FN1-200-5 seam welder can weld steel drum directly without spot-welding.

II.Feature

The welder has the following functions:

1. Adjust welding pressure evenly.

2. Stepless adjusting the welding speed

3. Freely adjust the current and heat

When upper and lower weld rollers wear out, adjust the hand wheel above the pneumatic cylinder to keep the original distance.

III. Technical Data

| Description | Unit | Data |

| Rated capacity | KVA | 200 |

| Rated voltage | V | 380 |

| Rated current | A | 526 |

| Frequency | HZ | 50 |

| Continuous capacity | KVA | 140 |

| Continuous current | A | 370 |

| Duty cycle | % | 50 |

| Secondary floating voltage | V | 6.8~7.6 |

| Secondary voltage regulation | 2 | |

| Welding speed | m/min | 0~7 |

| Thickness of maximum weldment | mm | 2+2 |

| Rated welding thickness of weldment | mm | 1.5+1.5 |

| Extension elongation of electrode arm | mm | 1100 |

| Adjustable top electrode strode | mm | 135 |

| Maximum working pressure | N | 6000 |

| Compressed air consumption | m3/h | 2.5 |

| Air pressure | MPa | 0.5 |

| Cooling water consumption | L/h | 4000 |

| Motor power | KW | 1.5 |

| Weight of welder | kg | 2700 |

| External dimension (length × width × height) | mm | 4300×1550×2570 |

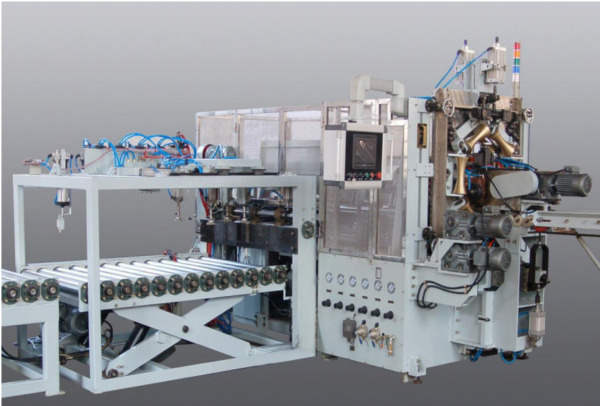

Option 2: Spot welding+ resistance seam welding machine—with automatic sheet loading/unloading device

Option 3: Fully automatic welding line

Working efficiency: 360-420pcs per hour(6-7 pcs per minute)

Diameter range: 560/571mm, customized accept

Length range: 900-1025mm

Material thickness range: 0.7-1.2mm.

Digital panel control, easy for operation.

Automatic electrode adjustment, Automatically loading/unloading the workpiece, automatically rolling and seam welding.

Company Introduction

Wuxi Longterm Machinery Technologies Co., Ltd is a professional manufacturer of steel drum,bitumen drum, open drum manufacturing machine with more than 30 years of history.

We are leading supplier of complete turkney solution for 55 gallon (US) & 44 gallon (UK) steel drum production line manufacturing equipments. We are improving technologies all the time and developing drum machinery market. We provide customers with valued solutions including automatic pre-curling &gluing machine,automatic hole punching &locking machine, flangers & curlers machine,W-Beader& corrugator machine, automatic sheet rolling, resistance longitudinal seam welding,assembly &seaming machine,drum painting spray booth,drying oven,silk printing machine etc..

Due to professional engineer team, highly automatic, simple operation and reliable quality equipment, Our machineries have been exported to many countries, such as Qatar, Australia, Bangladesh, Vietnam, India, Ukraine, Mexico, etc..

We are longterm company, and we will provide Longterm Quality Machinery and Longterm cooperation for the customers from all over the world.

Customers Visiting

Our Columbia customer is very interested in our welding machine

The biggest steel drum manufacturer from Indonesia visited our factory

Packaging Details

Standard seaworthy packing

Reviews

There are no reviews yet.