Description

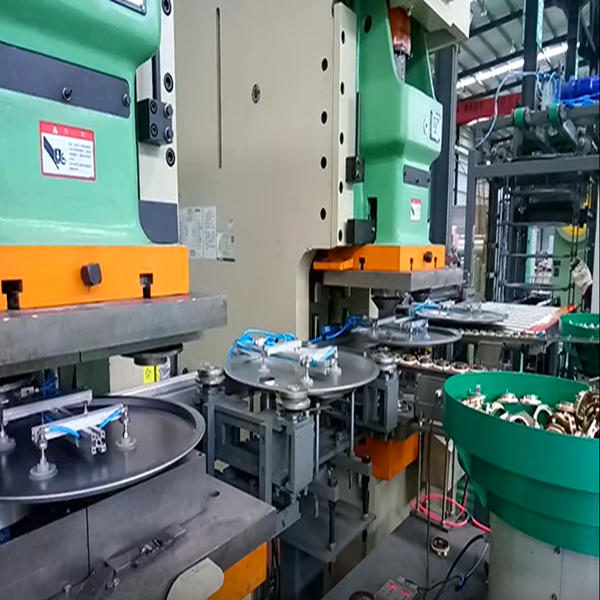

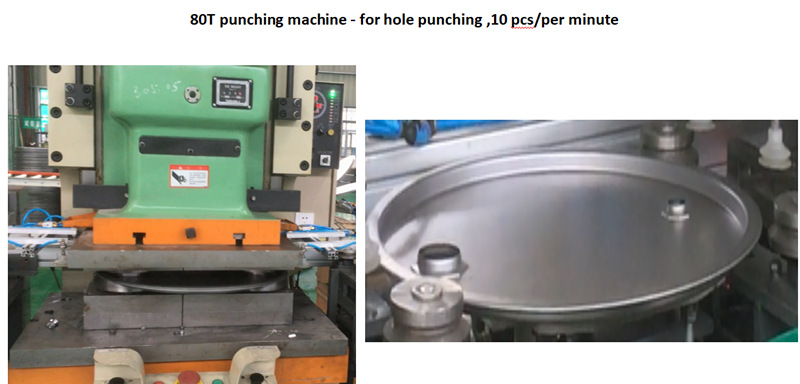

1. 80T punching machine-for hole punching machine

Speed: 10pcs/per minute

2. 80T punching machine – for locking

Speed: 10 pcs/per minute

Part of drum making machinery

1. Drum body straightening & blanking line(Cover straightening line)

Sheet thickness:0.8~1.2mm, Sheet coil width:660~1250mm

Max coil diameter:1650mm, Coil ID:φ508/φ610

Coil weight≤10T, Decoiler speed: 5-50m/min

Mitsubishi PLC, Servo motor driving control

2.Cover/bottom production line

2.1 160T punching machine – for cover/bottom cover blanking

One machine capacity: 10sets/min(10 pcs cover/10pcs bottom)

Cover blanking diameter. 650mm

Cover material width: 1250mm

Cover/bottom Straight conveyor Cover/bottom bending conveyor

3.Automtic pre-curling&gluing

(with seal glue/gelatinize) speed:10pcs/min; 10g /pcs glue

4. Drum body flanger and curler machine, speed: > 6pcs/min

The drum will be loaded to the machine automatically through conveyor, the machine will automatically check the drum body and lift it to a suitable places, then the carriage plate will move forward, the drum body will be flanged and expanded, then automatically lift down, the carriage plate will automatically move back(when the carriage plate is back, the machine decompression will be loading state, which will save energy). The drum body will go down and be unloaded on the conveyor.

Machine size: 3800*710*1600mm

Machine weight: 5000kgs

Power: 18KW

Capacity:>6pcs/min

5.W-beader& corrugator machine

Capacity: 6pcs/min, Power: 15KW

The conveyor will automatically load in the drum body, the machine will automatically check the drum body and lift it to a suitable places, then the carriage plate will move forward, the reinforced ring roller will lift up and press on the drum body, then automatically lift down, the carriage plate will automatically move back(when the carriage plate is back, the machine decompression will be loading state, which will save energy). The drum body will go down and be unloaded on the conveyor.

6.Drum assembly&seaming machine, speed: >6pcs/min

Manually put the cap on the assembly machine, the conveyor will load on the cap and drum body into the machine and assembly together. The assembly machine adopts double motors, separate driving, double main spindles. The carriage plate adopts imported linear guided with high accuracy and small friction.

Machine size: 3800*900*1700mm

Machine weight: 9000kgs

Power: 55KW

Capacity:>6pcs/min

7.Painting booth

4 sets pray pump(Chongqing Changjiang)

13 sets pray nozzle(American Nordson)

4500*3400*2500mm painting booth

Stainless steel sink and paint pipe line

Edge curl and paint repair device

Three-jaw painting rotation clamping device

8. Finished product

Customer visiting

Our services : Engineers available to service machinery overseas.

Engineer team were installing machine in Bangladesh.

Packaging &Shipping

Packaging Details: Standard seaworthy packing

Delivery Time: 45 days after receving your advance payment.

FAQ

To enable me give you correct proposal for correct machines, please tell me following details:

A: Technical drawing/Size of the steel drum you want to manufacture

B: What’s the capacity per shift/day?

Reviews

There are no reviews yet.